Application Background

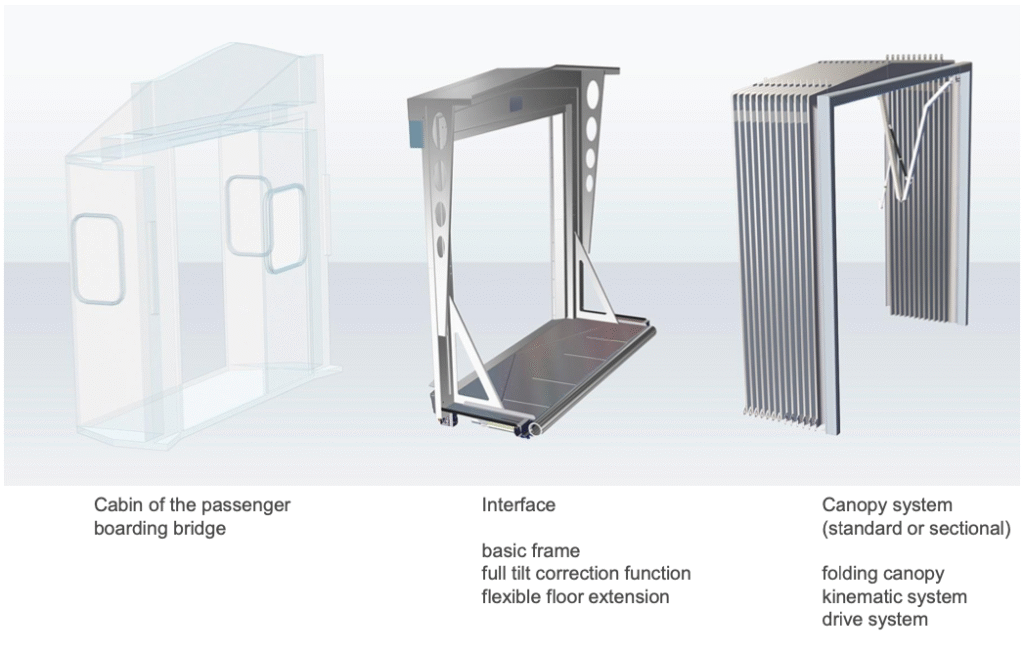

Passenger boarding bridges play a critical role in modern airports by providing a safe and efficient connection between terminal buildings and aircraft.

To accommodate different aircraft models and parking positions, boarding bridges must extend, retract, and adjust their position smoothly and reliably.

Electric linear actuators operating on 220V AC power are commonly used in push–pull systems of passenger boarding bridges, where controlled linear motion and precise positioning are essential.

Role of the 220V Electric Linear Actuator

In passenger boarding bridge systems, the 220V electric linear actuator is typically used to:

- Control the extension and retraction of the bridge structure

- Assist with fine positioning during aircraft docking

- Maintain stable positioning once the bridge is aligned

- Enable safe and predictable motion for passengers and operators

The actuator operates as part of a larger mechanical and control system, focusing on smooth motion and secure holding rather than lifting loads directly.

Operating Conditions and Safety Requirements

Passenger boarding bridges operate in demanding conditions that require strict safety and reliability standards:

- Outdoor exposure to rain, wind, dust, and temperature variation

- Frequent operation throughout the day

- High safety requirements due to direct passenger use

- Zero tolerance for unexpected movement or positioning errors

In this context, actuator reliability is not optional—it is a fundamental safety requirement.

Advantages of Electric Actuators in Boarding Bridge Systems

Compared to hydraulic or manual mechanisms, electric linear actuators provide clear advantages in airport bridge applications:

- Precise and repeatable motion control

- Lower maintenance requirements

- Cleaner operation without hydraulic fluids

- Easier system diagnostics and monitoring

- High positioning accuracy for aircraft docking

These benefits contribute to safer operations and reduced maintenance costs for airport operators.

Proven Reliability in Infrastructure Applications

Airport boarding bridges operate year-round in real-world conditions, often with minimal downtime allowed.

Electric linear actuators used in these systems must demonstrate consistent performance over long periods.

Actuators that perform reliably in airport environments prove their suitability not only for aviation infrastructure, but also for other critical industrial applications requiring safety and precision.